I have a Screamer kit, but it needs...

something beyond the gain, tone, volume...

That looks promising. I never use batteries, but it made sense to leave space, and it'll have a metal clip to hold it in place which'll be rivetted into position. I suppose the various parts should actually be on the

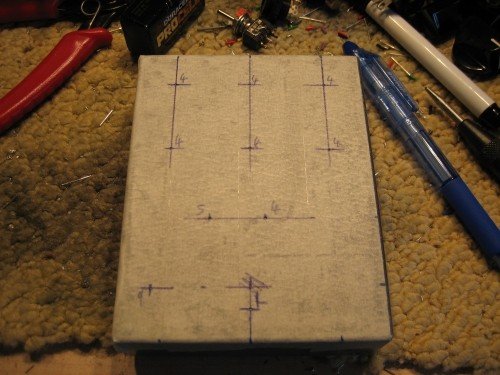

inside but that's easily rectified later. I'm not using the BYOC jack sockets because I prefer the enclosed type. Next step, measure up, put on some masking tape and mark the positions of the holes:

Okey. I punched the centres of the holes through the tape, then removed it (it gums up the bit and leaves a residue if you drill through it). Marked the holes with a dry-wipe marker (permanent pen can leech through the paint), including how many steps each hole will take on the stepped drill-bit.

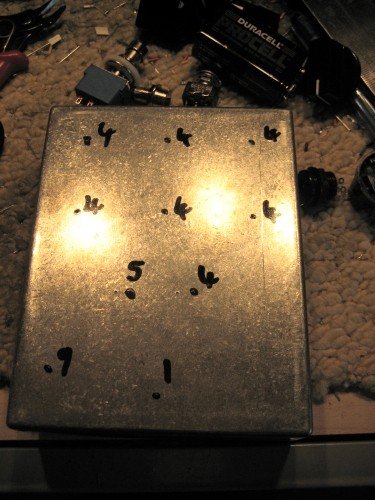

Drilling. Sides first - note the drill vice. Don't want to snag the bit and lose a wrist. The drill table is a bit rusty as you can see - I really need to ix the shed roof!

Skip a bit. I got fed up with drilling and just used a machine-gun on the other holes. Turned out better than I'd expected.

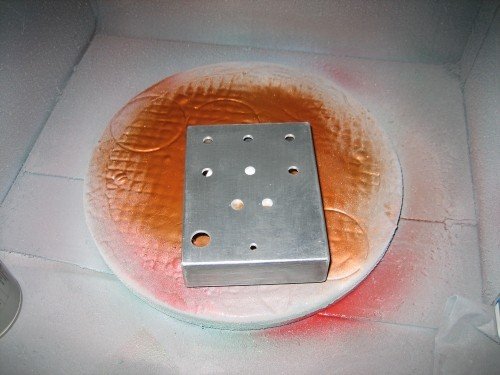

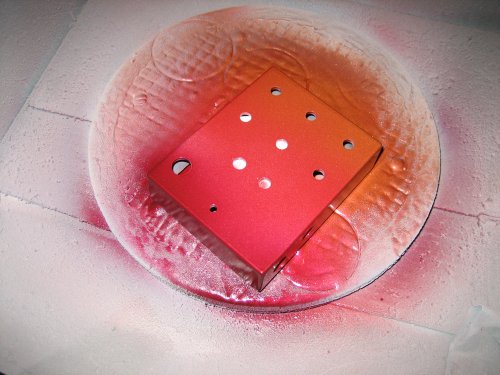

Sanded the enclosure so the paint would grip properly, then degreased with isopropanol and wiped clean with kitchen paper. Note the high-tech spray booth - two thirds of a cardboard box, a cake turntable and the lid from a spraycan to hold the enclosure above the turntable - this prevents it getting "glued" on with the paint. So many painful lessons learnt...

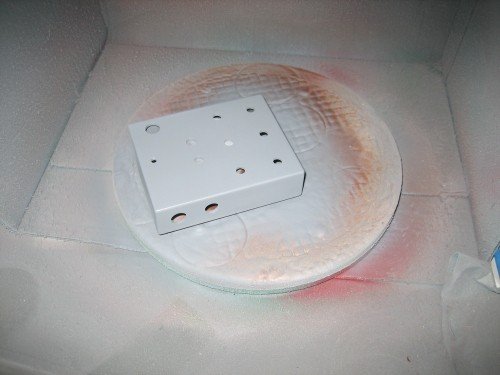

And some primer. Two coats, because, erm, that's how many I always do.

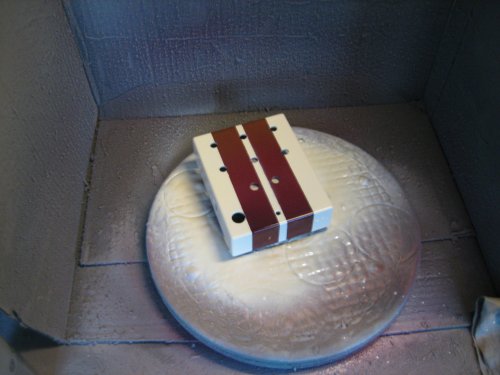

I'm going with two big fat stripes.

Here's the basecoat paint - this'll form the stripes tomorrow. One coat of colour, two of lacquer. The lacquer's gone on really nicely - this should look like it's been dipped in glass. I think it's Ford Aztec Bronze, Nissan something or other and Daewoo Ruby Red. The main colour will be white, I think. Something classy (for a change).

I didn't get a picture with the masking tape on; I wanted to leave it there as short a time as possible. Two strips, then a quick blast of white and ivory paint (thought it'd look a bit "aged" but there's not much contrast), then off comes the tape, quick as possible. The tape did fray a little at the edges unfortunately, but it looks passable.

Next step is to put on a LOT of lacquer in several coats. I want to remove any apparent border between the two sets of paint.

Day Two!

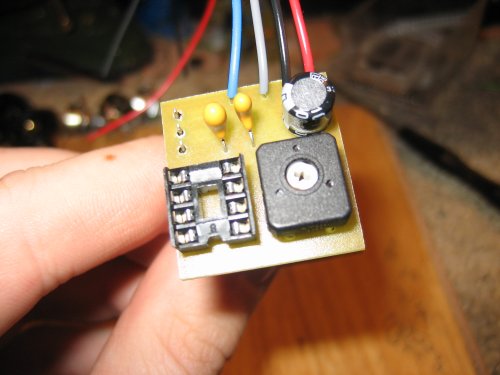

First job today was to make up the board for the booster. It's a basic 386-N4 based dealie; 10uF power decoupling cap, 0.1uF input and output caps, 470k trimpot on the input - I want the end result to be usable as a clean boost, and without padding the input I know some of my guitars will clip the 386.

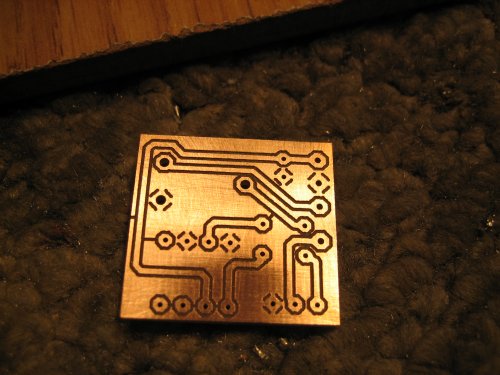

Here's the board as it came off the CNC router - design took about 40 minutes.

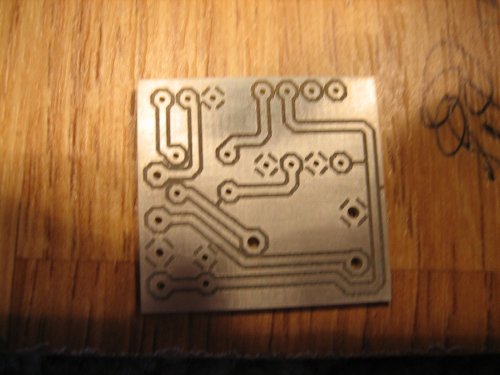

Then into the tinning tank for 20 minutes.

And populated - originally I wanted to mount it onto a pot, but in the end it's on shortish flying leads.

Next up is the midboost switch. Just a simple SPDT doodah that switches between the two caps supplied in the kit.

I'll skip the tedious detail of populating the BYOC board - I socketed the diode slots so I could experiment a little (currently a 3mm orange LED and two 914s), and changed out the carbon resistors for metal films wherever I had the right values.

On to the assembly - took 2-3 hours.

You can see the bigger pot in the middle - it's a Fender no-load tone pot for the feedback loop. When turned up to full it disconnects the wiper from the far end lug. The downside is that it then turns "backwards" - fully clockwise is no feedback, fully counterclockwise is 100% feedback.

Had a bit of difficulty with the booster board - just some cack-handed soldering. Finally got it all working though, and it is magnificent.

The knobs are, left to right, top row first, booster, feedback, power supply sag (for the screamer board only). Lower row is for the screamer - Drive, Tone, Volume.

There's a lovely range of sounds - clean boost, mild breakup, crunch, BREWTAL GAIN distortion, huge thick fuzz sounds, thin spluttery fuzzes, zippery glitchy fuzzes, howling feedback and much more.

I am very, very pleased. The insides could be neater but that's no real problem. Just need to rivet the battery clip in and it'll be complete. Ace. The boost knob is backwards too, so I'll reverse the wires at some point, and the sag control - currently 47k - could do with being a lower value as the action is all in the first little bit of the turn. I'll swap for a 4.7k pot.